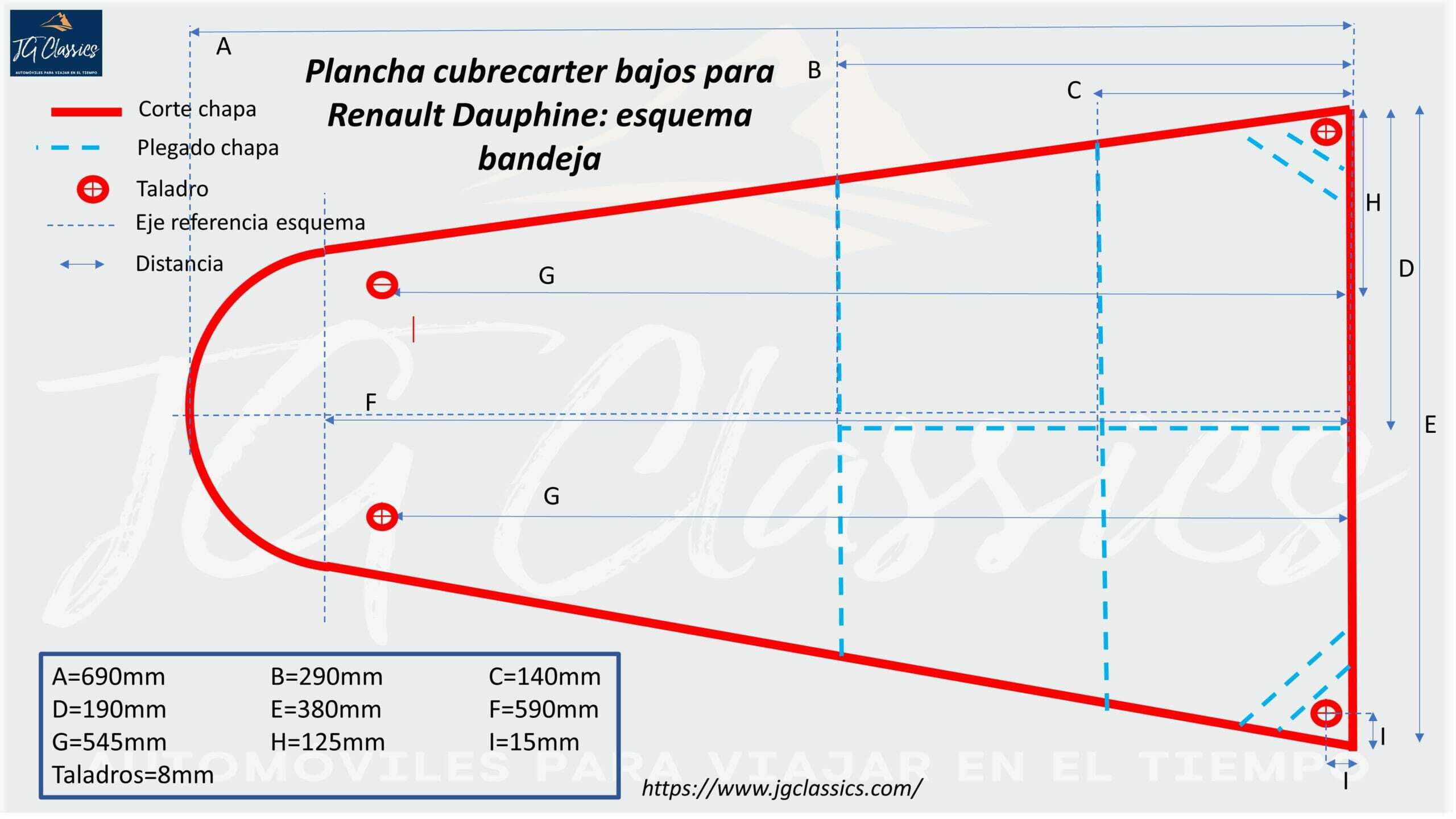

Phase 0 - Measurements, drills and dimensions

Before starting and sharing the details of the execution, we wanted to share with you a couple of diagrams with the information of the measurements and dimensions.

These measurements work on a Renault Dauphine so if you own one and want to make your own skid plate, this information will save you planning time and adjustments.

I recommend that you make a cardboard template: it will be much easier for you to make the cuts and, above all, to make the small adjustments that you will surely need.

Although the measurements (expressed in mm) correspond exactly to those we have used, the drawings have not been made with any CAD tool, so the scale will not be entirely accurate. However, the drawings have been made from an actual photo of the template, so we do not expect any major variations in scale. Again, I would like to point out that the measurements expressed ARE completely adjusted to the real case.

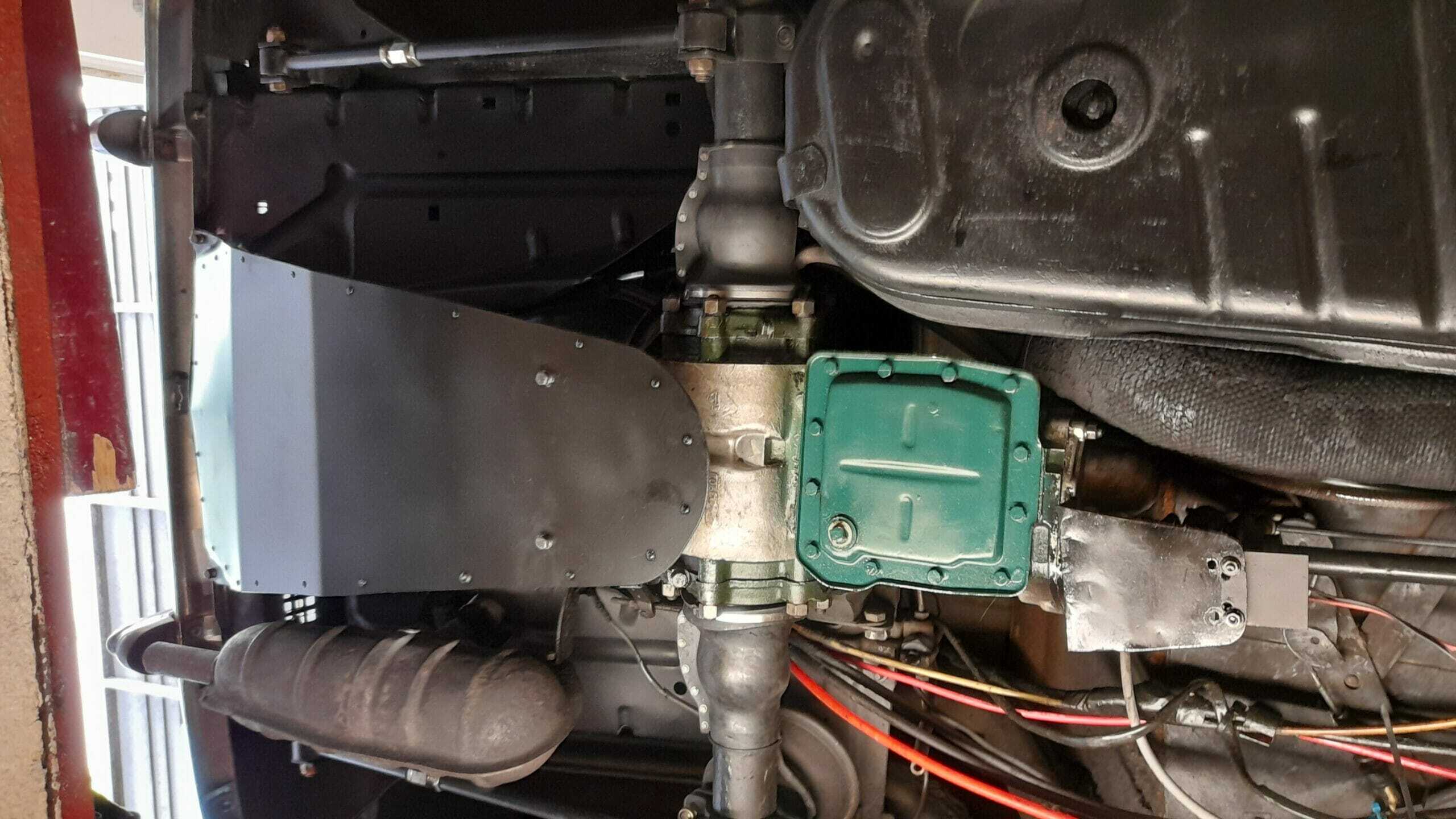

Photo gallery phase 0

This is the image gallery of the initial phase. Actually, in this “phase zero” there are only two images with the theoretical scheme of the tray and the brackets. You can click on each of the photos to see the information in detail. As always, if you have any questions or doubts, you can contact us and we will be really happy to answer and help you.

How to carry it out: some practical suggestions

If you decide to carry out the project, my recommendation is to start by preparing a cardboard template (any packaging cardboard will do). This will allow you to “play” with the shape, drill hole locations, etc. So once you have the template ready, cutting on the steel sheet will be easy and fast.

In the case of brackets, I recommend that you cut the sheet metal to a length slightly longer than the sum of the two sides of the sheet. This is because in the fold you will lose some length. For example, if you have 90mm in length at the longest part (measurement A) and 45mm at the shortest part (measurement G), my suggestion is that before bending the total length is 90+45+5=140mm, with that extra 5mm allowing you to make the bend without the sides losing length.