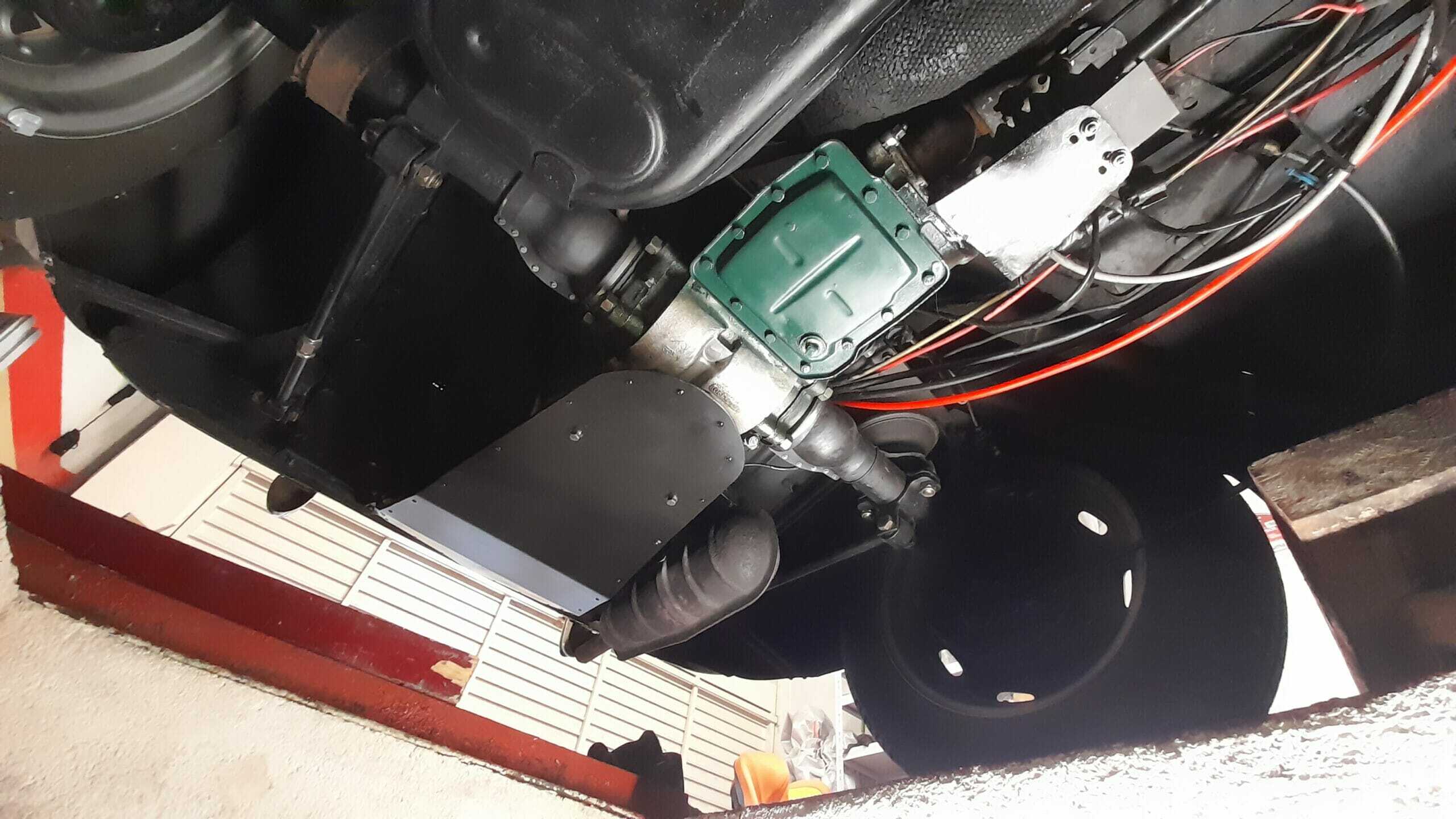

Phase 8 - Final installation on the vehicle

This is the final phase. There really isn’t much to comment on. Once the four anchors have been prepared and the machining of the plate has been completed. we only have to screw it by its four points.

We have used M6 screws. We found this to be a reasonable measure, although it is true that this installation is subject to little dynamic stress so it is not a critical point.

At the time of installation you may have to slightly adjust some of the four anchor points, but as they are all made of sheet metal, or are fixed to it, you will not have any problem if you have to make a slight adjustment. At this point, installation in the car will only take a few minutes.

As a last point to note, I suggest that you use serrated washers or

glover DIN 127

to avoid loosening of the screws. Combined with normal flat washers, they ensure complete fastening without the screws backing out.

Photo gallery phase 8

This is the image gallery of the final phase of installation on the underbody of the vehicle. You can click on each of the photos to see the description. As always, if you have any questions or doubts, you can contact us and we will be happy to answer and help you.

Noises or vibrations. Are there?

This is a question that can be very pertinent. When installing a sheet metal fairing on the undercarriage, you may wonder if there may be vibrations or aerodynamic noises (air hissing or similar). In the case of this tray installed in this car as written in these pages, the answer is NO. So far, we have not found either.

However, in the case of vibrations, you would have an alternative (which in the case of the MGA we do use) which is to insert silent blocks between the plate and the anchor points. They are available with male thread, with female thread, with mixed male-female thread (like the one in the photo), and in all possible sizes. They are inexpensive and very

easy to find

on the market